Overview of Overhead Conveyor Systems

Overhead Conveyor Systems are material handling systems that utilize overhead space in a facility to transport products, parts, or materials from one location to another. Unlike traditional floor-based conveyor systems, overhead conveyors hang from the ceiling or an elevated structure, freeing up valuable floor space for other operations.

These systems can handle a wide range of products, from lightweight to heavy items, and are commonly used in industries such as automotive, electronics, food processing, packaging, and garment manufacturing. They are highly versatile and can be designed to suit specific needs, including straight, curved, inclined, and declined paths.

Types of Overhead Conveyor Systems

There are several types of Overhead Conveyor Systems available, each with its unique features and applications:

Monorail Overhead Conveyor

Monorail overhead conveyors consist of a single rail that supports and guides the movement of the load carriers. These conveyors are ideal for light to medium-duty applications and are commonly used in assembly lines, paint shops, and warehouses.

Power and Free Overhead Conveyor

Power and free overhead conveyors offer greater flexibility compared to monorail systems. These conveyors have two tracks: one powered and the other free. The system allows the load carriers to stop, accumulate, and reroute independently, making them ideal for complex processes like sorting, buffering, and transporting products in batches.

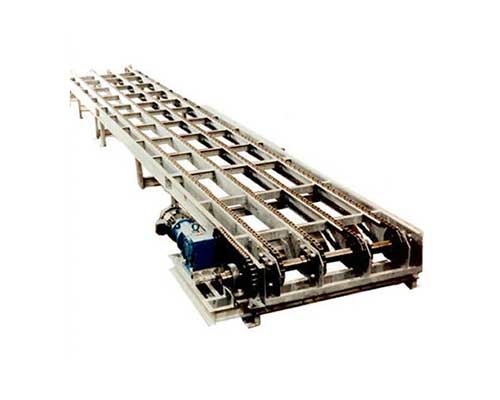

I-Beam Overhead Conveyor

I-Beam overhead conveyors are robust and heavy-duty systems that are ideal for transporting large, heavy items. These conveyors feature I-beam-shaped rails and trolleys, offering greater strength and durability, making them suitable for industries such as automotive and heavy machinery manufacturing.

Enclosed Track Overhead Conveyor

Enclosed track overhead conveyors feature a closed structure that protects the conveyor chain from dust, dirt, and debris, ensuring smooth and uninterrupted operation. These systems are widely used in cleanroom environments and industries where hygiene is a top priority, such as food and beverage processing.

Inverted Overhead Conveyor

Inverted overhead conveyors are designed to carry products from the bottom rather than hanging them. These conveyors are commonly used in industries where products need to remain clean, as they prevent any dust or debris from falling onto the products.

Benefits of Overhead Conveyor Systems

Overhead Conveyor Systems offer numerous advantages for businesses across different industries:

Maximizing Floor Space

One of the biggest benefits of overhead conveyors is that they utilize overhead space, freeing up floor space for other operations. This is especially important in industries where space is limited, and maximizing floor space can lead to increased productivity and better workflow.

Improved Efficiency

Overhead conveyors provide a continuous, automated flow of materials, reducing the need for manual handling and minimizing downtime. This leads to faster production cycles, reduced labor costs, and improved overall efficiency.

Enhanced Flexibility

These systems can be designed to handle a wide range of products, from small components to heavy machinery. The flexibility of overhead conveyors allows businesses to customize the system according to their specific needs, making it suitable for various applications, including assembly, sorting, painting, and storage.

Reduced Risk of Damage

By transporting products overhead, these systems reduce the risk of damage caused by collisions, mishandling, or accidental drops. This is especially important for delicate or fragile items that need careful handling.

Improved Safety

Overhead conveyors enhance workplace safety by reducing the need for forklifts, pallet jacks, and other material handling equipment on the floor. This minimizes the risk of accidents and injuries, creating a safer working environment for employees.

Cost Savings

While the initial investment in overhead conveyor systems may seem significant, the long-term cost savings are substantial. Businesses can save on labor costs, reduce product damage, and increase production efficiency, leading to a faster return on investment.

Why Choose Perfection Engineering Corporation?

Perfection Engineering Corporation has earned a stellar reputation in the industry for its commitment to delivering high-quality Overhead Conveyor Systems that meet the diverse needs of its clients. Here are some reasons why businesses in Delhi and beyond choose Perfection Engineering Corporation as their trusted conveyor partner:

Expertise and Experience

With years of experience in the material handling industry, Perfection Engineering Corporation has developed in-depth knowledge and expertise in designing and manufacturing conveyor systems. The company’s team of skilled engineers and technicians work closely with clients to understand their specific requirements and provide tailor-made solutions.

Cutting-Edge Technology

Perfection Engineering Corporation is equipped with state-of-the-art manufacturing facilities and uses the latest technology to design and produce high-quality conveyor systems. The company is committed to innovation, ensuring that its products are built to withstand the demands of modern industries.

Custom Solutions

Every business has unique material handling needs, and Perfection Engineering Corporation understands this. The company offers customized Overhead Conveyor Systems that are designed to optimize workflow, enhance productivity, and improve overall efficiency.

Quality Assurance

Quality is at the heart of everything Perfection Engineering Corporation does. The company follows stringent quality control measures at every stage of production to ensure that each conveyor system meets the highest standards of performance, durability, and reliability.

After-Sales Support

Perfection Engineering Corporation goes the extra mile to ensure customer satisfaction. The company provides comprehensive after-sales support, including installation, maintenance, and repair services, to keep the conveyor systems running smoothly and efficiently.

Competitive Pricing

Despite offering top-quality products and services, Perfection Engineering Corporation ensures that its pricing remains competitive. The company’s cost-effective solutions provide excellent value for money, making it an ideal choice for businesses looking to invest in overhead conveyor systems.

Applications of Overhead Conveyor Systems

Overhead Conveyor Systems are widely used across various industries, including:

Automotive: For transporting vehicle components during assembly.

Manufacturing: In production lines for moving parts, tools, and equipment.

Food Processing: To handle food products in a clean and hygienic environment.

Textile: For garment handling and sorting in the textile industry.

Warehousing: For material handling and inventory management in warehouses and distribution centers.